Working Principle

A solenoid dosing pump is a form of positive displacement pump which uses a diaphragm and solenoid assembly to displace the fluid into the discharge line. The solenoid 'drive' consists of an electromagnet and spring assembly, which is activated/deactivated with a series of electrical impulses. As the solenoid is activated, the electromagnet pushes the diaphragm, which displaces the fluid. As the solenoid is deactivated, the spring mechanism returns the diaphragm, allowing more fluid from the suction line to enter the chamber ready for delivery. The dosing aspect is determined by programming the pump to a rate of delivery. The rate can be arbitrarily set by the operator or according to an external signal.

Some solenoid dosing pumps also allow a variable stroke length and stroke rate. This allows a very high 'turndown' i.e. a very high ratio between the maximum and minimum potential flow rates. The Electro Magnetic Metering pumps are used in low pressure and low flow applications. The drive unit solenoid coil consumes less energy than motor driven pumps. The pump capacity is varied by both stroke length and speed controls. These pumps are operated by 230V,50Hz, Single phase. The pumps include standard accessories like Foot Valve or Y-strainer, Injection Valve and LDPE Hose.

Material of Construction of Wetted Parts

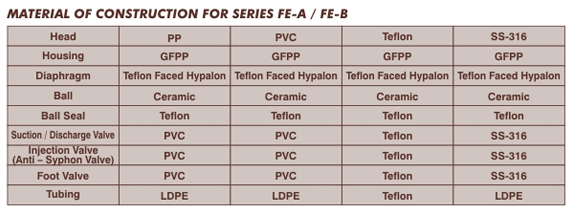

1. AISI 304SS/AISI 316SS/ALLOY20/POLYPROPYLENE/PTPE/PVC

Salient Feature

Pump Capacity is varied by both stroke length and stroke frequency adjustments.

Steady state accuracy±2%

Linearity & Flow Repeatability±3%

GENERAL SPECIFICATION

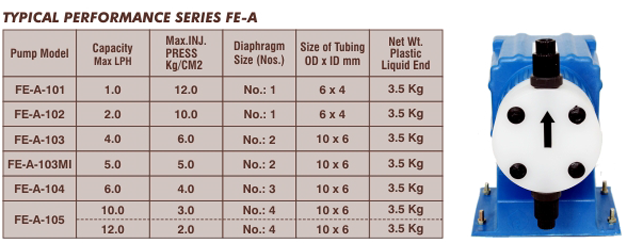

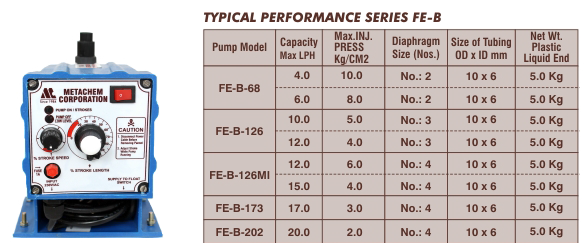

Max. Flow rate: Up to 20 L/Hr.

Max. Pressure: Up to 12 Kg/cm2.

A solenoid dosing pump is a form of positive displacement pump which uses a diaphragm and solenoid assembly to displace the fluid into the discharge line. The solenoid 'drive' consists of an electromagnet and spring assembly, which is activated/deactivated with a series of electrical impulses. As the solenoid is activated, the electromagnet pushes the diaphragm, which displaces the fluid. As the solenoid is deactivated, the spring mechanism returns the diaphragm, allowing more fluid from the suction line to enter the chamber ready for delivery. The dosing aspect is determined by programming the pump to a rate of delivery. The rate can be arbitrarily set by the operator or according to an external signal.

Some solenoid dosing pumps also allow a variable stroke length and stroke rate. This allows a very high 'turndown' i.e. a very high ratio between the maximum and minimum potential flow rates. The Electro Magnetic Metering pumps are used in low pressure and low flow applications. The drive unit solenoid coil consumes less energy than motor driven pumps. The pump capacity is varied by both stroke length and speed controls. These pumps are operated by 230V,50Hz, Single phase. The pumps include standard accessories like Foot Valve or Y-strainer, Injection Valve and LDPE Hose.

Material of Construction of Wetted Parts

1. AISI 304SS/AISI 316SS/ALLOY20/POLYPROPYLENE/PTPE/PVC

Salient Feature

Pump Capacity is varied by both stroke length and stroke frequency adjustments.

Steady state accuracy±2%

Linearity & Flow Repeatability±3%

GENERAL SPECIFICATION

Max. Flow rate: Up to 20 L/Hr.

Max. Pressure: Up to 12 Kg/cm2.

Description

Selection Chart

Selection Chart